Powering the Future of Energy Storage

Atlantic Equipment Engineers delivers high-purity metal powders and custom alloys engineered to meet the demands of modern battery and energy storage technologies.

From lithium-ion batteries powering electric vehicles to large-scale renewable energy storage systems, our powders provide the purity, consistency, and performance that manufacturers and researchers rely on.

Our high-purity metal powders and compounds enable high energy density, improving efficiency across electrodes while offering cost-effective and sustainable solutions for large-scale adoption.

Engineered Metal Powders for Next-Generation Batteries

At AEE, we specialize in ISO-certified materials engineered for advanced energy storage. Our materials meet the strict requirements of:

- Battery electrodes (anodes and cathodes).

- Current collectors.

- Advanced storage systems such as solid-state and flow batteries.

With tailored particle sizing, controlled morphology, and exceptional purity, AAE ensures your materials deliver results at every stage, from R&D to full-scale production.

Why Energy & Battery Developers Trust American Equipment Engineers

From R&D labs to gigafactory-scale production, developers trust AAE for:

- ISO-certified, high-purity metal powders and compounds

- Technical consulting for battery-specific alloys

- Custom particle sizing for electrode optimization

- Complete lot traceability and documentation

- Reliable supply chains and fast delivery worldwide

- High energy density for extended storage capacity

- Cost-effective solutions for large-scale deployment

- Sustainable processing to meet modern energy goals

Products, Grades & Technical Specifications

Our battery-grade powders include:

- Lithium powder – anode materials.

- Nickel powder – cathode and electrode applications.

- Calcium powder – stabilizing alloys.

- Cobalt powder – high-energy density cathodes.

- Copper powder – current collectors.

- Silicon powder – advanced anode materials.

- Manganese powder – electrode stabilization

- Iron powder – cost-effective electrode blends

- Silicon carbide powder – high-performance additives

- Metal oxide powders – for diverse storage chemistries

- Custom alloys – tailored for next-gen R&D

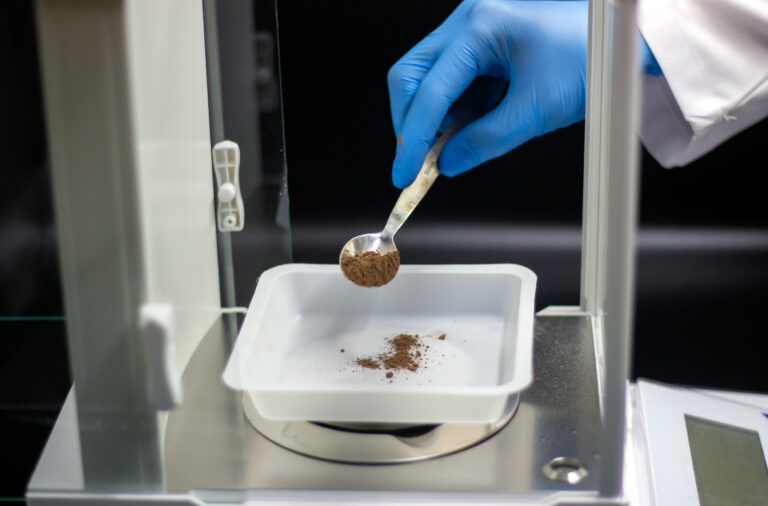

Every batch undergoes rigorous purity testing and is optimized for application-specific performance. With their high energy density and sustainable design, our metal powders and compounds provide cost-effective options for both R&D and large-scale deployment.

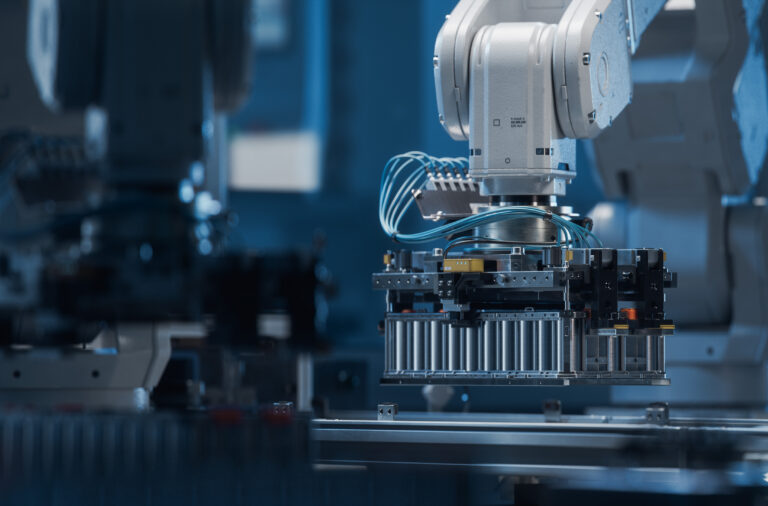

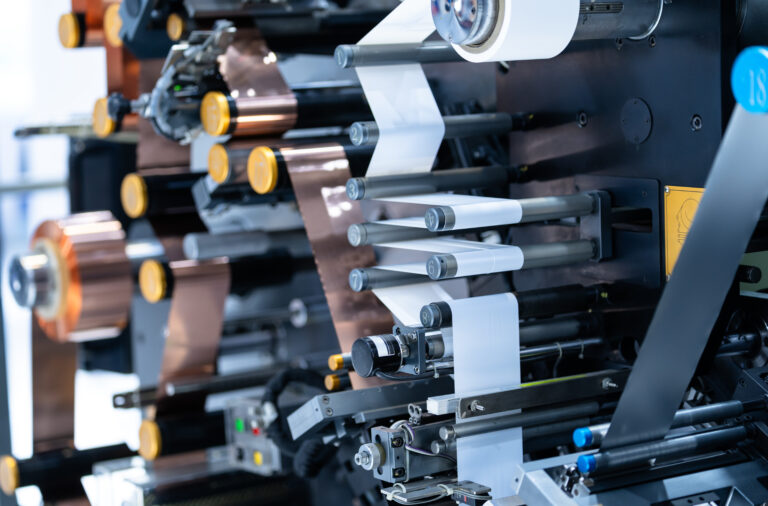

Applications & Processes We Support

AEE supports the full spectrum of energy storage applications:

- Research and prototyping for next-generation chemistries

- Powder metallurgy for electrodes, current collectors, and components

- Custom alloy design for lithium-ion, solid-state, and flow batteries

- Additive manufacturing for 3D printing of battery components

- Renewable energy storage systems

Key Benefits & Features of American Equipment Engineers Materials

- Consistent, high-purity metal powders.

- Wide range of particle sizes and alloy compositions.

- ISO-certified production and traceability.

- Expert R&D and technical support.

- Fully customizable alloy solutions.

- Supply chain reliability with fast delivery options.

- High energy density materials for compact, powerful storage.

- Performance-enhancing alloys for advanced applications.

- Cost-effective solutions for large-scale manufacturing.

- Sustainable sourcing and processing methods.

Custom Solutions & Technical Support

Looking for a unique alloy or process optimization? Our team of experts provides:

- Custom alloy development for specific chemistries.

- Process optimization for improved yield and performance.

- Flexible order sizes from R&D batches to production volumes.

Quality Assurance & Customer Trust

Atlantic Equipment Engineers is committed to the highest standards of quality:

- ISO-certified manufacturing.

- Rigorous testing and purity validation.

- Full traceability and documentation.

- Trusted by universities, R&D labs, and global manufacturers alike.

Q: What types of energy storage systems do your materials support?

Our powders are used in lithium-ion, solid-state, flow batteries, and renewable storage systems.

Q: Can you assist with alloy or electrode design?

Yes, our experts provide direct technical support and custom solutions.

Q: What are typical lead times for battery-grade metal powders and compounds?

Most orders ship within 1–3 business days, depending on batch size.

Q: Are your materials ISO-certified?

Yes, all our powders are produced and tested under ISO-certified processes.

Q: Do you offer custom particle sizes or alloy composition?

Yes, we specialize in tailoring powders to meet specific performance requirements.