Engineered Metal Powders Built for Demanding AM Workflows

From the laboratory bench to flight-ready parts, factors such as material quality, particle size distribution, and logistics efficiency determine the success or failure of additive manufacturing (AM) and 3D printing (3DP) processes.

AM and 3DP manufacturers have demanding density and mechanical targets to hit, particularly as they move from the research and development phase to scale-up and serial production. Consistent material lots, predictable flowability of additive manufacturing metal powders, and robust documentation are critical.

In this guide, we will explore how Atlantic Equipment Engineers, a leading 3D printing metal powders supplier, supports AM and 3DP programs with high-purity metals and alloys, controlled particle sizes and morphologies, rapid and reliable global shipping, and ISO-anchored quality systems. We will discuss the use-cases for various metal powders in common AM workflow as well as quality assurance and logistics concerns, before finishing with a buyer’s checklist to help you to de-risk your procurement processes.

How Atlantic Supports AM and 3DP Processes

Atlantic offers one of the largest and broadest catalogs of additive manufacturing metal powders available anywhere. We supply pure metals and both standard and custom alloys, all specifically engineered for 3D printing and additive manufacturing with carefully controlled particle sizes and morphologies.

Example representative alloys:

Just some of the alloys we can supply include:

Aluminum

Our 4047 (AL-4047), 6061, and 7075 aluminum alloy powders for 3D printing offer spherical particles and various AM-appropriate size cuts.

Stainless & tool steels

We offer various stainless and tool steels, including 15-5PH, 17-4PH, and our 18Ni 300 maraging steel, which is prized for its exceptional strength and toughness.

Cobalt-chromium

Our various products within the cobalt-chromium family include CoCrMo, CoCrMoW, and CoCrW, available in multiple size types.

Copper and iron

We supply both spherical Cu powders and low-oxygen spherical Fe powders (FE-104-S) engineered for AM processes.

Custom alloy powders and engineering collaboration

Need something specific? Whatever the properties you are seeking, our team can work collaboratively with you to tailor alloys and develop new materials for R&D and production in 3D printing and additive manufacturing.

Particle Engineering That Matters in AM

Precision and consistency of materials are essential to AM and 3DP processes. Atlantic offers standardized “type” cuts (including 0–45 μm, 15–45 μm, 15–53 μm, 45–150 μm) aligned to common needs across powder bed fusion and directed energy deposition workflows, helping engineers to match feedstock to laser and beam parameters and nozzle specs. Spherical metal powder morphologies such as our low-oxygen spherical iron are engineered specifically for AM, supporting flowability and packing.

Atlantic holds ISO-9001 certification and proudly upholds a quality culture that extends far beyond the certificate, supporting lot-to-lot consistency and documentation with every batch.

From Prototype to Production: Logistics and Lead-Time

Speed matters in manufacturing, and the majority of Atlantic materials are available for global shipment within two business days with flexible packing solutions to align with customer specifications. Whether you are seeking materials for rapid prototyping, ready to up production, or seeking to reduce line-down risks, we are here to help.

Shorter lead times and documented lots offer quicker parameter tuning, faster new product introduction, and easier PPAP and FAI scheduling.

Process-to-Metal Powder Mapping: Quick Guide

The best materials for your needs will depend on the types of additive manufacturing and 3D printing required for your processes.

Metal Powder Bed Fusion (PBF/SLM/EBM)

For these processes, manufacturers should prioritize 15–45 μm or 15–53 μm “type” cuts with spherical morphologies to balance flow, layer density, and melt pool stability.

Directed Energy Deposition and Laser Metal Deposition (DED/LMD)

Larger cuts, typically in the 45–150 μm range, are ideal for the higher feed rates required for DED and LMD processes.

Material Extrusion and Other Processes

Fine, uniform particle sizes and a spherical shape are ideally suited to material extrusion and related processes.

Industries and Applications: Where Are AM and 3DP Used?

Additive manufacturing is increasingly utilized across numerous industries due to its flexibility and the high customizability of components it offers. Just some of the industries that commonly utilize additive manufacturing and 3D printing include:

Space and Aerospace

Titanium, nickel, aluminum, and cobalt play a vital role in the components required for the exacting needs of the aerospace and space industries. Atlantic is able to offer the quality of materials and the comprehensive documentation required to meet aerospace industry expectations, with immediate shipment and flexible ordering.

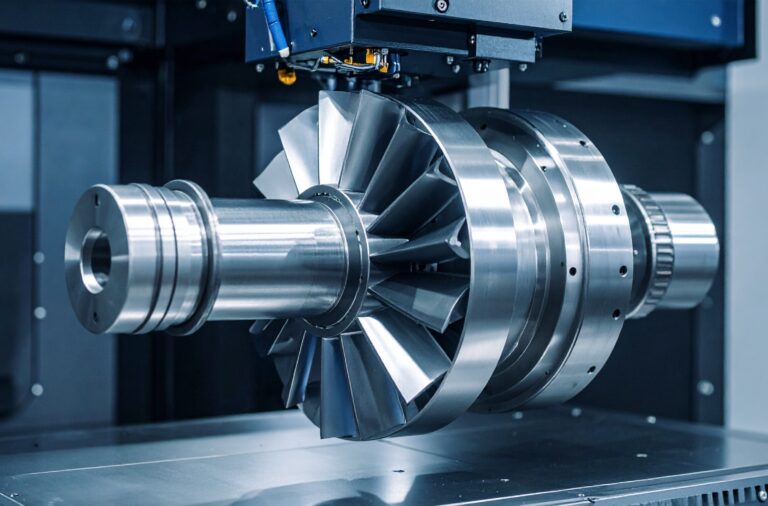

Energy and Turbines

3DP and additive manufacturing can allow for the engineering of more efficient turbines and the construction of the structural parts required for the many new technologies emerging in the rapidly developing energy space.

Research and Laboratory Processes

Laboratory research and development is critical across virtually all manufacturing sectors as well as academic and scientific research. Atlantic’s large catalog breadth and ISO-certified materials serve both university and industrial labs’ AM requirements.

Why Choose Atlantic for AM and 3DP Materials?

Founded in 1963 to supply high-purity metals and alloys to advanced research and manufacturing programs, Atlantic has decades of materials sourcing and distribution experience. Our ISO-anchored quality culture goes far beyond certification, with regular quality controls performed to ensure we continue to meet the exacting needs of our clients’ processes.

We understand the unique needs of additive manufacturers and 3D printing processes, which is why we supply clear size and morphology options across our numerous alloys, allowing you to make the best decision for your needs.

With most products stocked for immediate shipment, two-day shipping available worldwide, and flexible packaging options to align with customer specifications, we ensure you have the materials you need, right when you need them.

And if you need something we don’t have in our catalog, our engineering team will work closely with you to customize or develop materials for your precise requirements.

Quality, Documentation and Traceability: What Buyers Can Expect

Because we believe in transparency and traceability at every stage of the manufacturing supply chain, we offer easy and centralized access to technical documentation for every product, streamlining contract review and ordering to get your materials into your hands more quickly.

Our ISO certification and internal quality assurance practices ensure you receive lot consistency and robust data with every order, whether you purchase from us once or become one of our valued regular customers.

Our moisture-resistant barrier packaging can be customized so that your order is packed to your specifications, and comprehensive labeling ensures both traceability and enhanced shipping safety.

Superior Materials for Additive Manufacturing Success

Motorized additive manufacturing and 3D printing do not succeed on the quality of machines alone. These processes also require the metal powders and compounds used to be engineered to exacting standards and delivered reliably.

Atlantic’s high-purity metals and alloys, controlled particle sizes, ISO-9001 backed quality system, and two-day global shipping make us a dependable partner for engineers, whether you are conducting R&D prototyping or scaling up to full production runs. And, if you need something specific to meet a particular production need, our experienced engineers will work with you to create an alloy perfectly designed to your specifications.

Whether you are developing next-generation turbine blades, lightweight aerospace parts, or medical implants, the right materials supplier minimizes risk and accelerates innovation throughout the research, development, and production process. Atlantic’s dedicated 3D printing and additive manufacturing catalog ensures that metals powders are not generic commodities, but precision-processed feedstocks designed for success in PBF, EBM, DED, and material extrusion workflows.

Explore our 3D Printing & Additive Manufacturing metal powders catalog to find metal powders and alloys with the properties and particle sizes aligned with your process needs. You can request a quote on our website or contact our engineering team to discuss custom specifications, packaging options, and delivery schedules that keep your additive manufacturing projects on track.