Atlantic Equipment: A Reliable Titanium Powder Supplier

-

TI-502

TITANIUM NITRIDE POWDER

- Formula TiN: 61.89 g/mol

- Purity 99+

- Particle Size 1-5 Micron

-

TI-NM-31

TITANIUM CARBIDE NANO POWDER

- Formula TiC

- Purity 99% min

- Particle Size 40 nm

-

TI-104-S

TITANIUM POWDER, SPHERICAL

- Formula Ti: 47.88

- Purity 99.8% min

- Particle Size -325 mesh

-

TI-303-S

TITANIUM CARBIDE, SPHERICAL

- Formula TiC

- Purity 99.5 min

- Particle Size 106-45 microns

What is Titanium Powder?

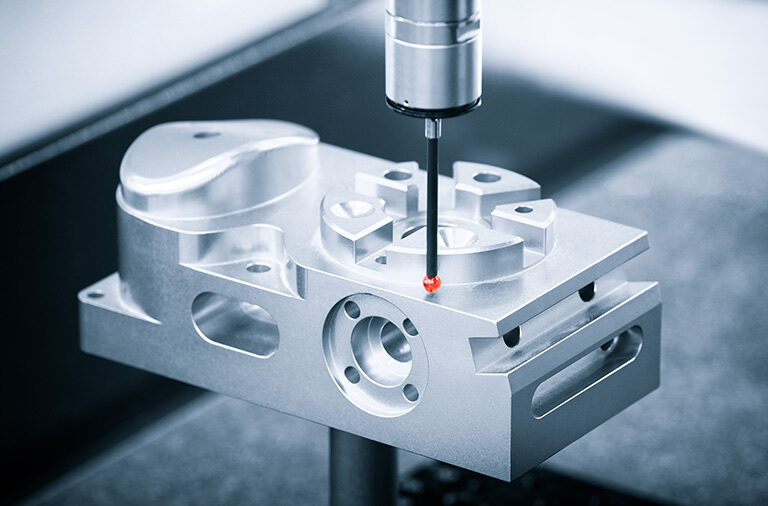

Titanium powder is a form of titanium that has been reduced to a fine powder consistency. It can be used in various industrial and manufacturing processes, such as additive manufacturing (3D printing), coatings, and metallurgy. In additive manufacturing, titanium powder is used as a feedstock material to create complex parts with high strength-to-weight ratios. In metallurgy, titanium powder can be used as a raw material for creating titanium alloys, which have a wide range of industrial and aerospace applications.

What Is Titanium Powder Used For?

Titanium powder can be used for several industrial and manufacturing applications, including:

Additive Manufacturing (3D Printing)

Titanium powder is used as a feedstock material to create complex parts with high strength-to-weight ratios, such as aerospace and biomedical components.

Coatings

Titanium powder creates coatings that provide corrosion resistance and increased hardness.

Metallurgy

Titanium powder can be used as a raw material for creating titanium alloys, which have a wide range of industrial and aerospace applications, such as aircraft components, medical implants, and sporting equipment.

Chemical Production

Titanium powder can be used as a catalyst in some chemical reactions and as an oxidizing agent in the production of titanium dioxide.

Pigment Production

Titanium dioxide is extensively used as a white pigment in paint, paper, and plastic production.

Other Industrial Uses

Titanium powder it can also be used as a deoxidizer and degasser in steel production and in specific electronic applications.

What We Offer

Atlantic Equipment Engineers has been a trusted supplier of high-purity metal powders for almost 60 years. We always prioritize quality and specialize in packing and shipping orders of any size. With AEE, you'll always get high-purity titanium powder that meets all your specifications at a competitive price. We offer titanium powder in various forms, including a range of particle sizes, and now also in a spherical form. Atlantic Equipment Engineers guarantees fast shipping and attentive and knowledgeable customer service every step of the way.

Why Turn to Atlantic Equipment

As industry leaders, Atlantic Equipment Engineers is ready to tackle your high-purity titanium and titanium powder needs. Our commitment to excellent customer service is reflected in our industry certifications. We are proud to be an ISO 9002 certified company, certified to the 9001:2008 standard by DNV. We have experience serving a wide range of clients working in different market sectors and industries—we're here to help you meet your business goals.

Q: How long does titanium last?

Titanium is a highly durable and long-lasting material, making it well-suited for various industrial and aerospace applications. The service life of titanium components can vary depending on the specific application and the conditions they are exposed to.

In general, titanium is resistant to corrosion and degradation and can last for decades in many applications. For example, titanium alloys are used in aerospace and marine applications because they are lightweight, strong, and resistant to corrosion. In these applications, titanium components can last for decades, even in harsh environments.

For medical implants, titanium is a preferred material due to its biocompatibility and longevity. Implants made of titanium can last for many years, and in some cases, for the patient's entire lifetime.

It's important to note that the actual longevity of a titanium component depends on various factors, such as the specific alloy used, the manufacturing process, and the environmental conditions of the application.

Q: When does titanium melt?

The melting point of pure titanium is approximately 1,675 °C (3,047 °F). However, the melting point of titanium alloys can vary depending on the specific alloy and the manufacturing process used.

Titanium alloys are typically used in high-temperature aerospace, power generation, and chemical processing applications. These alloys are designed to have a higher melting point than pure titanium, so they can withstand higher temperatures without melting.

Note that the melting point of a material is not the only factor determining its suitability for high-temperature applications. Other properties such as thermal conductivity, thermal expansion, and creep resistance also play essential roles in determining the appropriateness of a material for high-temperature applications. Titanium alloys have lower thermal conductivity than pure titanium. This means the heating process must be carefully controlled to avoid overheating and melting the parts.

Q: When titanium was discovered?

Titanium was discovered in 1791 by William Gregor, a British clergyman, and amateur geologist. Gregor discovered titanium while examining a black sand sample from a beach in Cornwall, England. He noticed that the sand contained a metallic element that was not iron. He named this new element "menachanite" after the nearby parish of Menaccan. It was later determined that menachanite was actually titanium.

However, pure titanium was not produced until 1910. The German chemist Matthew A. Hunter was the first to produce pure titanium by reducing titanium tetrachloride (TiCl4) with magnesium. This method is still used today to produce commercial-grade titanium.

It wasn't until the 1930s that titanium began to be used in industrial applications. The first commercial use of titanium was in manufacturing pigments for paint and paper using titanium dioxide. Titanium's aerospace application began in the 1940s and 1950s and has been used in the aerospace industry ever since.

Q: Which titanium alloy is bulletproof?

Titanium alloys are known for their high strength and lightweight properties, but they are not bulletproof. While titanium is much stronger than aluminum and most steels, it is still not as strong as other materials, such as ceramics or certain polyethylene.

Some titanium alloys have been used to make body armor, but, again, it is not considered bulletproof. These alloys are typically used in conjunction with other materials, such as ceramics or aramid fibers, to provide a higher level of protection against bullets.

It's important to note that no material is completely bulletproof, and the level of protection provided by any body armor can vary depending on the type of bullet, the velocity at which it travels, and the distance from which it is fired.

In summary, while titanium alloys can be used to make body armor, they are not considered bulletproof, and their performance will depend on the specific alloy and the construction of the armor.

Q: Where can I buy titanium powder?

Atlantic Equipment Engineers can help you with all of your titanium powder needs. You can view our product catalog for different types of titanium powder that is available.

Q: Is titanium safe to drink from?

Titanium is commonly used to make bottles, cups, and other drinking vessels. Titanium is a biocompatible metal, which means that it is not toxic to humans and does not react with the human body. It is also resistant to corrosion, which means it does not rust or degrade over time.

Titanium is also considered an inert metal and does not react with most acids or bases. This means that it will not leach any harmful chemicals into your drink, making it a suitable material for drinkware.

It's important to note that when titanium is used to make drinkware, it is typically alloyed with other metals to improve its strength and durability. These alloys are also considered safe for drinkware, but it's always a good idea to check the product information or contact the manufacturer to confirm if the drinkware is safe.

Additionally, to ensure safety, it's essential to keep in mind that the drinkware should be cleaned and maintained correctly to avoid any contamination.